Lightning strikes occur millions of times each year across the UK, making proper protection systems essential for any building. However, lightning protection system installation is only the first step. Regular maintenance is what keeps your system functioning when you need it most.

At Lightning Protection Testing UK, we understand that maintenance isn't just about ticking boxes. It's about protecting human life, safeguarding electronic systems, and ensuring your building meets all legal requirements. Our fully qualified engineers provide lightning protection maintenance services in Bridge that keep your lightning protection system operating at peak performance.

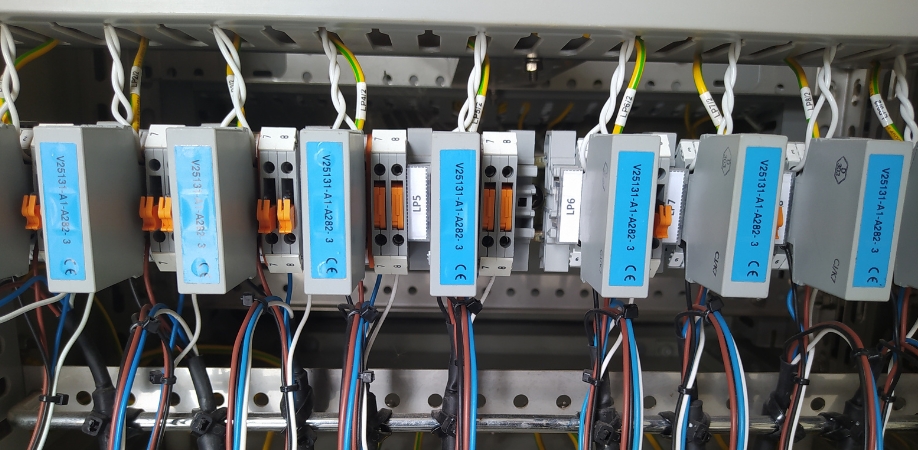

A lightning protection system consists of several crucial components that work together to safely conduct electrical energy to earth. Each component requires specific maintenance attention to ensure the entire system remains effective.

Air terminals form the first line of defence, positioned strategically across your building's highest points. These components face constant exposure to environmental conditions and require regular inspection for corrosion, damage, or displacement. Down conductors provide the pathway for electrical energy, running from air terminals to earth connections. These conductors must maintain their integrity and proper connections throughout their length.

The earthing system represents the foundation of effective lightning protection. Earth rods and connections must maintain low resistance levels and remain free from corrosion. Surge protection devices protect sensitive electronic systems but can degrade over time, especially after repeated electrical events.

Under the Electricity at Work Regulations 1989, building owners and employers are legally required to maintain lightning protection systems in safe condition. Is lightning protection a legal requirement? This isn't optional – it's a legal duty that carries serious consequences if neglected.

What is BS EN 62305? BS EN 62305 provides the technical framework for lightning protection system maintenance. While this British standard requires at least annual testing, it strongly recommends interim maintenance, particularly for high-risk sites such as petrochemical facilities, buildings with explosive atmospheres, or structures housing vulnerable electronic systems like data centres and hospitals.

Many insurance policies in Bridge require documented maintenance and inspection records for lightning protection systems. Failing to maintain your system properly can invalidate claims in the event of lightning damage, leaving you facing potentially devastating costs.

Our preventive maintenance plans help you avoid costly repairs while ensuring your system stays fully functional and compliant year-round. These tailored programmes address the reality that annual testing alone isn't sufficient for optimal system performance.

Regular inspections between annual testing cycles allow us to identify potential issues before they become serious problems. Our Bridge engineers conduct thorough visual inspections, checking for corrosion, loose connections, weather damage, or signs of tampering. We clean and re-secure air terminals, down conductors, and connection clamps as needed.

Structural bonding checks ensure all metalwork remains properly connected to your lightning protection system. Building modifications, thermal expansion, and normal wear can affect these crucial connections. We verify bonding to structural steel and external metalwork maintains its integrity.

Surge protection device monitoring forms a crucial part of our maintenance service. These devices can degrade over time or after repeated surges, yet many systems are left unchecked between annual tests. Manufacturers often recommend replacing surge protection devices every 3-5 years, or sooner if compromised.

While annual testing measures your system's performance at a specific moment, regular maintenance ensures it performs consistently throughout the year. Industry reports show that over 60% of system failures during testing are due to poor or irregular maintenance, including corroded or disconnected conductors, damaged air terminals, and faulty surge protection devices.

Testing provides a snapshot of system condition through electrical measurements and visual inspection. Maintenance involves ongoing care that prevents deterioration and addresses issues before they affect system performance. Both elements work together to ensure comprehensive protection.

Our detailed reports document all maintenance activities, providing the records required for insurance compliance and regulatory requirements. These reports track system condition over time, helping predict when components may need replacement and ensuring you stay ahead of potential problems.

At Lightning Protection Testing UK, we provide more than just compliance — we deliver peace of mind.

All our engineers are trained and certified to current British lightning protection standards.

We serve commercial, industrial, and residential properties across the entire UK.

Fast inspections and repairs after storm activity or suspected lightning strikes.

Detailed test certificates and inspection records suitable for insurers and regulatory authorities.

From hospitals and schools to heritage-listed buildings — we’ve done it all.

Whether it's a failed test result or visible wear and tear, we respond quickly to get your system back to full working order. Our reactive repair service in Bridge addresses issues identified during routine inspections or following adverse weather events.

Component replacement may involve air terminals, down conductors, clamps, or earth rods that have suffered damage or degradation. We use high-quality materials that match or exceed original specifications, ensuring repairs maintain system integrity.

Connection repairs address bonding issues that can develop over time. Building movement, thermal cycling, and corrosion can affect electrical connections. Our engineers re-establish proper bonding where connections have degraded or become disconnected.

System modifications may be necessary when building alterations affect lightning protection compliance. We can re-route conductors, add additional protection points, or integrate updated surge protection devices to maintain full system effectiveness.

A lightning protection system should be serviced at least once a year to ensure it meets safety standards and functions correctly during storms.

Lightning protection maintenance involves checking conductors, air terminals, bonding, and earth electrodes to confirm the system is intact and compliant.

Lightning protection system maintenance is necessary to reduce the risk of structural damage, fire, or electrical failure caused by undetected faults.

Lightning protection system maintenance is a legal obligation under the Electricity at Work Regulations 1989 and BS EN 62305 in many UK sectors.

Lightning protection system maintenance costs typically range from £200 to £600 depending on the size, complexity, and number of test points.

You can know if your lightning protection system is working by having it regularly tested for continuity and earth resistance during scheduled inspections.